The MORE project, an innovative initiative funded by the European Union, celebrated the culmination of its European Industrial Doctorate (EID) research and training program at a successful final event. The event showcased the achievements of 8 early-stage researchers (ESRs) who presented key outcomes from their individual projects addressing challenges in the construction, logistics, and forestry sectors.

MORE – Educating Europe`s Future Engineers in Next Generation Heavy Duty Mobile Machinery: Artificial Intelligence driven Robotisation, Energy Efficiency and Process Optimisation – is the first industry-academia partnership to jointly educate researchers on heavy-duty mobile machinery. It addresses the need for dramatic improvements in heavy-duty mobile machinery (HDMM) and fill the gap in related research and training. Over the past four years, the MORE ESRs have been equipped with a set of research skills including robotics, machine learning, energy systems, as well as transferable skills such as entrepreneurship and career management.

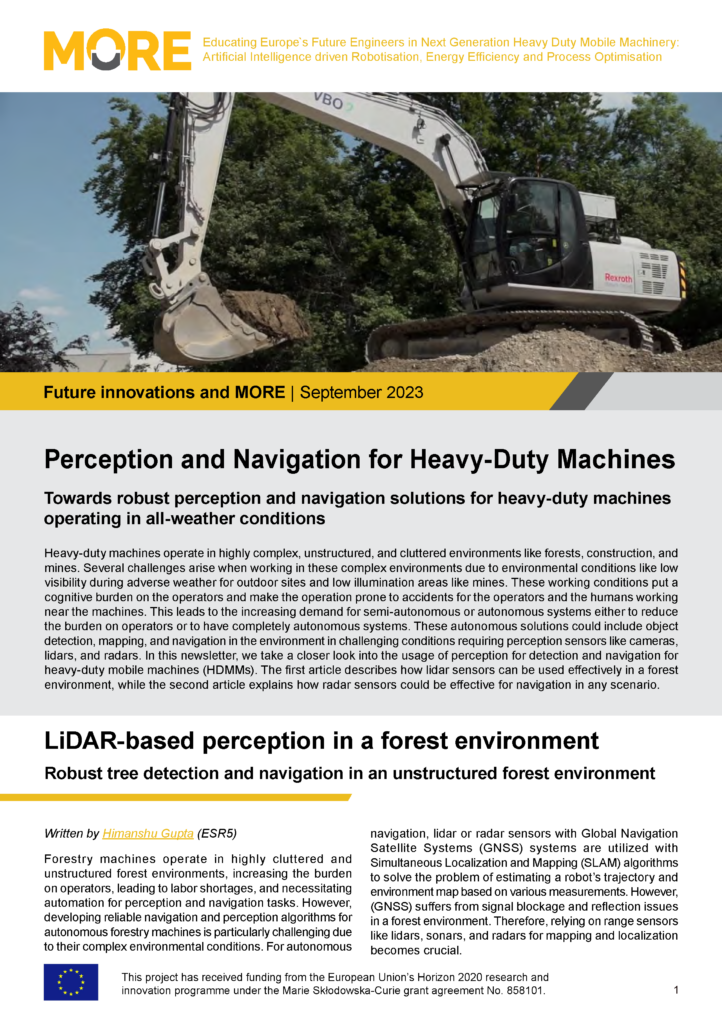

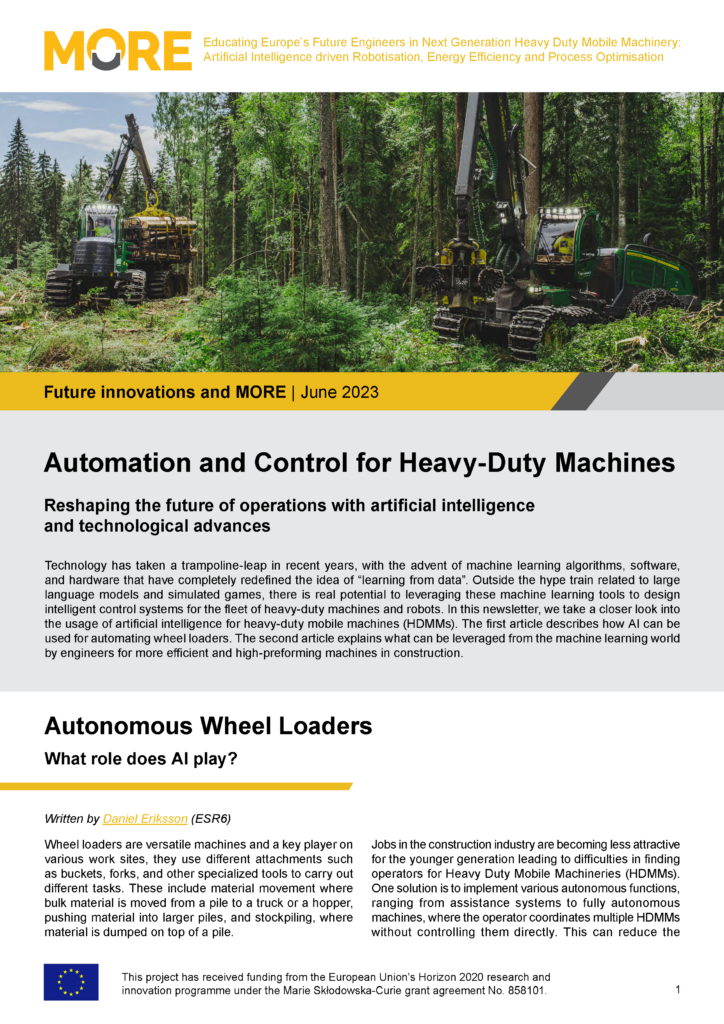

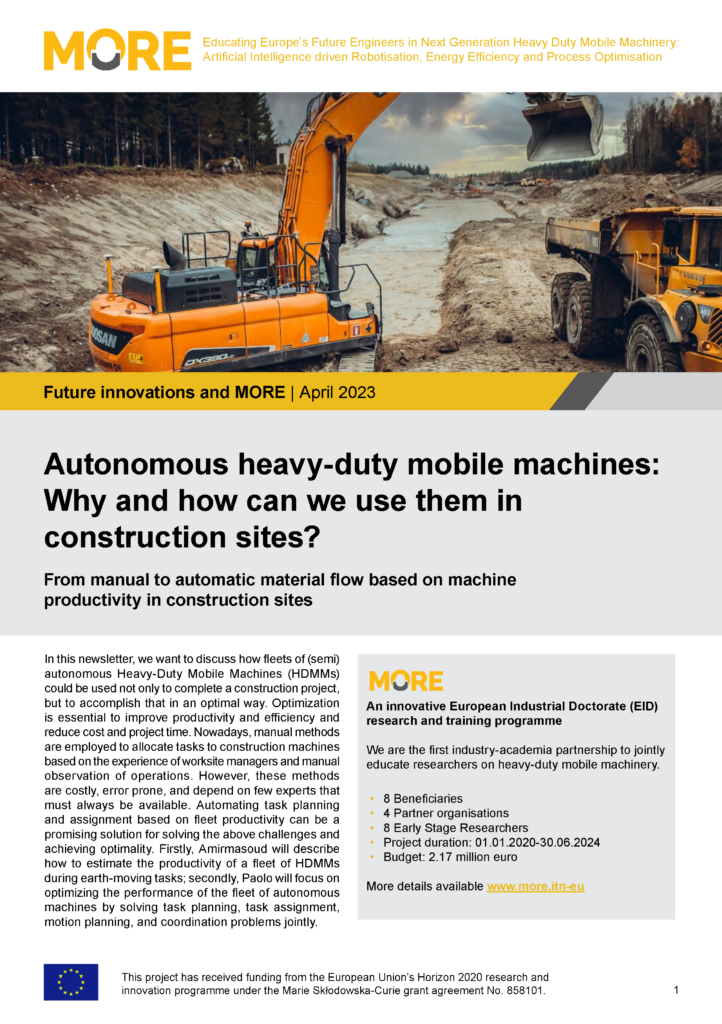

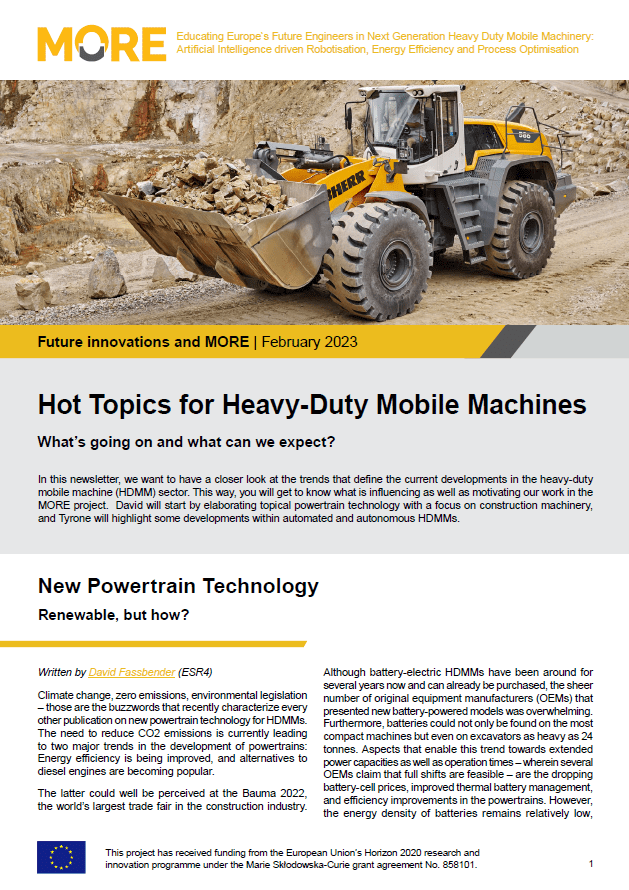

Held in Helsinki, Finland from 24 – 26 October, the MORE project’s final event marked a significant milestone in enhancing productivity and efficiency across key industries. Around 40 participants joined the event including HDMM company representatives, PhD students and members from the MORE network. The consortium, comprised of respected heavy-duty mobile equipment companies including J. Deere, Liebherr, Bosch Rexroth, HIAB, and Volvo CE, collaborated with four specialised academic groups to nurture a new generation of engineers equipped with cutting-edge knowledge and skills.

In addition to keynote lectures and a site visit to Aalto Robot Learning Lab, the event highlighted the accomplishments of the ESRs, unveiling innovative solutions resulting from digitalisation and artificial intelligence. The recordings from the MORE ESR presentations are available online.

Professor Reza Ghabcheloo, coordinator of the MORE project, Tampere University, shared his satisfaction with the ESRs’ journeys, stating, “This has been a very successful industrial doctorate program, we have achieved our goals, industry is happy of the results and would like to build a similar project, doctoral students are happy and wanted by industry after MORE.”

As Europe anticipates a future shaped by technology and human creativity, the MORE project exemplifies the synergy between academia and industry. This collaboration fosters a generation of engineers ready to leave a lasting impact on heavy-duty mobile machinery and the industries it serves. The ESRs have demonstrated that innovation has no boundaries when fueled by dedication and cooperation.